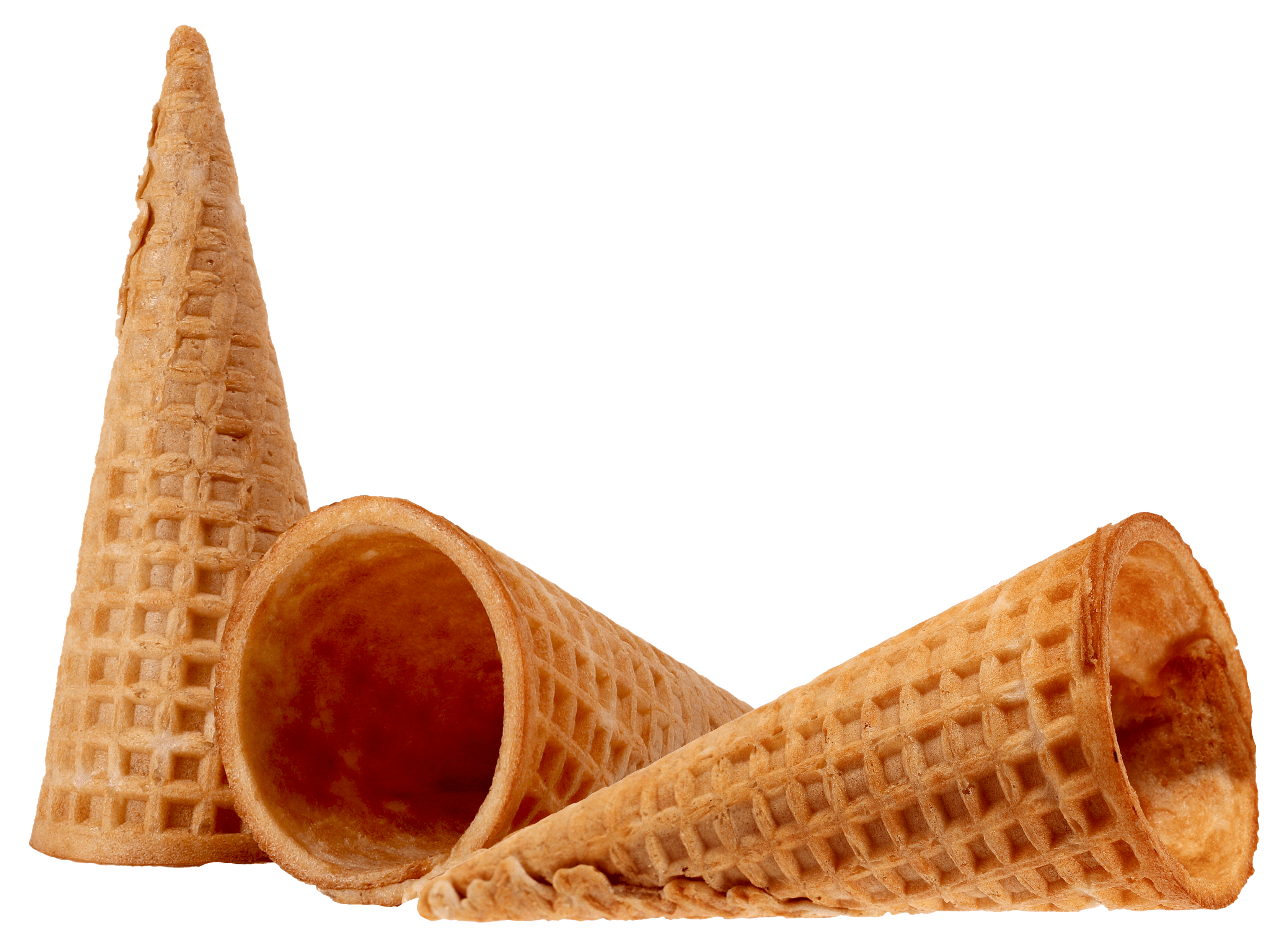

With over 30 years of multifaceted global experience, Laxmi Wafers N Cones went into commercial production in 2018 to fulfill the market need of natural, superior quality, ice cream cones that are distinct by their ‘Crunch & Taste’.

Located in the lap of the sub Himalayan rich green pastures of India in Mehatpur, Una, Himachal Pradesh, Laxmi Wafers N Cones has unique access to the freshest and finest natural ingredients - be it the flour that comes from the adjacent sun dried golden farms, pure sugar, or spring water infused with natural minerals that result in the baking of these delightful cones!

Furthermore, in its own humble way, Laxmi Wafers N Cones is being selective in its procurement of chemically infused agricultural produce, investing in research on natural alternative packaging materials,

recycling of waste, guiding and supporting our eco-system towards a happier and healthier world.

With the latest, high speed advanced technology imported machines and a recipe to match, delightfully tasty and crunchy cones are baked with minimal moisture, added strength and an unusually long shelf life.

Adjoined with a fully automatic multi-colored, multi-layered, sleeve manufacturing plant aided by a customized design team, it together with a hi-tech Baking and Rolling Cone plant, auto assembles the most hygienic, untouched by hand, finished products of global standards.

A highly skilled team of professionals ensure ‘unmatched quality and on-time performance’ at minimalist thereby providing an unrivalled opportunity of success to our customers.

Standard Crunchy Cone serves ice cream volumes varying from 100ml to 120ml. This popular cone size is largely used by branded ice cream manufacturers globally.

Mini Sugar Cone serves ice cream volumes varying from 50ml to 80ml. Just by changing the size of the sleeve/jacket the ice cream volume can be varied

It prevents cone damage in transit and storage, and enables the cone to retain its flavor and crunchiness over extended periods of time

Printed in varied size requirements, each sleeve is finished with a protective food grade overcoat and conforms to global standard guidelines